Ball screws / compact flange / diameter 12, 14 / pitch 4, 5, 10 / C7, C10 / steel / phosphated / 58-62HRC (Part Numbers - CAD Download)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- Catalog

- Technical Information

Dimensional Drawing

BSST·BSSR (K)·BSSZ (K)·BSRR (K)

View X-X

● Shaft Dia. 12, Lead 10

BSSR (K)·BSSZ (K)·BSRR (K)

View X-X

● Shaft Dia. 14, Lead 05

BSSR (K)·BSSZ (K)·BSRR (K)

View X-X

| Nut Type | Type | Accuracy Grade | Shaft Dia. | Lead | Screw Shaft | Nut | |||||

| Standard | F, P Configurable | [M] Material | [H] Hardness | [S] Surface Treatment | [M] Material | [H] Hardness | [S] Surface Treatment | ||||

| Standard Nut | BSST | — | C7 | 12 | 4 | EN 1.1203 Equiv. | Induction hardened 56 to 62HRC | — | EN 1.7264 Equiv. | Carburized 58 to 62HRC | [ ! ] Phosphate Conversion Coating |

| BSSR | BSSRK | C10 | 12·14 | 4·5·10 | Phosphate Conversion Coating | Phosphate Conversion Coating Coating treatment | |||||

| BSSZ | BSSZK | — | |||||||||

| BSRR | BSRRK | Low Temperature Black Chrome Plating | |||||||||

Specification Table

| Part Number | — | L | — | F | — | P |

| BSSZ1204 BSSZK1210  BSSR1204L BSSR1204L BSSR1405G BSSR1405G | — — — — | 200 370 370 370 | ||||

| — | F20 | — | P8 | |||

| (L Type Greased) | ||||||

| (G Type Greased) | ||||||

| Nut Type | Accuracy Grade | Part Number | 1 mm Increments | Y | Ball Dia. | Ball Center Dia. | Screw Root Dia. | Number of Circuits | Basic Load Rating | Axial Play Clearance | Twisting Direction | |||||

| Type | Screw Shaft O.D. | Lead | L | * F | * P | C (Dynamic) kN | Co (Static) kN | |||||||||

| Standard Nut | C7 | BSST | 12 | 04 | 150 to 795 | 15 | 8 | L-65 | 2.3812 | 12.6 | (10) | 2.5 turns, 1 row | 2.6 | 5.8 | 0.03 or Less | Right |

| C10 | BSSR BSSZ BSRR | 150 to 800 | 0.05 or Less | |||||||||||||

| BSSRK BSSZK BSRRK | 15 to 24 | 5 to 8 | L- (50+F) | |||||||||||||

| BSSR BSSZ BSRR | 10 | 150 to 800 | 15 | 8 | L-65 | 3.175 | 12.8 | (9.6) | 1.5 turns, 1 row | 2.85 | 4.95 | 0.10 or Less | ||||

| BSSRK BSSZK BSRRK | 15 to 24 | 5 to 8 | L- (50+F) | |||||||||||||

| BSSR BSSZ BSRR | 14 | 05 | 150 to 800 | 15 | 8 | L-65 | 14.5 | (11.2) | 2.5 turns, 1 row | 4.4 | 7.3 | |||||

| BSSRK BSSZK BSRRK | 15 to 24 | 5 to 8 | L- (50+F) | |||||||||||||

| * F and P are configurable for BSSRK, BSSZK, and BSRRK only. [!] F ≤ P × 3. [!] Y (Nut Motion Range) > (Nut Overall Length). kgf = N × 0.101972 | ||||||||||||||||

Alterations

| Part Number | — | L | — | F | — | P | — | (FC·KC, etc.) |

| BSSR1204 | — | 270 | — | SC7 |

| Alterations | Code | Spec. | Alterations | Code | Spec. | |||||||||||||

No Machining on Both Shaft Ends [ ! ]A nut is mounted to the temporary shaft before the product is shipped. | WNC | Does not machine any of the both shaft ends. Ordering Code WNC-S20-F80 [ ! ] Annealing may lower hardness on the annealed area + 25 mm fore and aft. [ ! ]S+F ≤ L/2 [ ! ]L- (S+F) ≤ Y+50 [ ! ] On the annealed area + 25 mm fore and aft, axis run-out may be larger than indicated by the Catalog standard. | Wrench Flats on Fixed Side Incomplete Hardened Area | SZC | Adds wrench flats on the fixed side shaft end.

crosses the wrench flats. | |||||||||||||

No Machining on Support Side Shaft End | NC | No machining added on the support side shaft end. Ordering Code NC | Keyway on Fixed Side Shaft End | KC | Adds a keyway on the fixed side shaft end. [NG] Not applicable to P = 5. KC = 1 mm Increments Ordering Code KC10 [ ! ]3 ≤ KC ≤ P × 3 KC ≤ F-1 | |||||||||||||

Ball Nut Orientation Reversed

| RLC | Changes the nut direction. Ordering Code RLC | Keyway on Fixed Side Shaft End | KLC | The position of keyway on fixed side shaft end can be specified. (Keyway dimensions are the same as KC.) [NG] Not applicable to P = 5. K, S = 1 mm Increments Ordering Code KLC-K5-S2 [ ! ]4 ≤ K+S ≤ P × 3 K+S ≤ F-1 | |||||||||||||

No Retaining Ring Groove on Support Side Shaft End | RNC | No Retaining Ring Groove on Support Side Shaft End. Ordering Code RNC [NG] Combination with FC is not available. | Flat Machined on Fixed Side Shaft End | SC | Adds a flat on the fixed side shaft end. SC = 1 mm Increments Ordering Code SC7 [ ! ]5 ≤ SC ≤ P × 3 SC ≤ F-1 | |||||||||||||

Change Support Side Shaft End Machining | GC | Changes the machining on the support side. For the screw shaft 12, Q is selectable from 6 or 8; for the screw shaft 14 , Q is selectable from 6, 8 or 10 G = 1 mm Increments Ordering Code GC-Q8-G20 [ ! ] 5 ≤ G ≤ Q × 3 [ ! ] Y dimension is shortened. [ ! ] No Retaining Ring Groove [ NG ] Combination with FC is not available | Flat Machined on Fixed Side Shaft End (2 Locations) SWC SGC  | SWC SGC | Adds two flats on the fixed side shaft end. SWC: 90° Position SGC: 120° Position 1 mm Increments Ordering Code SWC7 [ ! ]5 ≤ SWC·SGC ≤ P × 3 SWC·SGC ≤ F-1 | |||||||||||||

Change Support Side Shaft End Length | FC | Changes the length of the support side shaft end. FC = 1 mm Increments Ordering Code FC20 [ ! ]11 ≤ FC ≤ 20 [ ! ] Y dimension is shortened. [NG] Combination with GC is not available | Installing Special Temporary Shaft | TAS | Dedicated Temporary Shafts suitable for Ball Screws are installed. When removing Nut from Screw Shaft, always use Special Temporary Shaft. | |||||||||||||

General Information - Ball Screws

Ball Screw Selection Details

- Material: steel

- Coatings: uncoated, LTBC coating, phosphate conversion coating

- Heat treatment: up to 62HRC

- Precision category: C3, C5, C7, C10

- Precision classes: precision class, standard class

- Slope: 1 to 32 mm

- Outer diameter: 6 to 32 mm

- Length (mm): 100 to 2000

- Nut shape: round flange, square flange, compact flange, block shape

Description/Basics

Ball screws are intended for converting rotary motion to linear motion. This can also be done in reverse order from linear to rotary motion. With the ball screws, this is achieved extremely precisely due to their low play. In mechanical engineering, the ball thread drive is an indispensable feature and is indispensable in precision applications. These work in horizontal and vertical orientation, allowing to shift, raise and lower devices.

The ball screws are often driven by motors and shaft couplings, or manually via rotary/crank handles.

When utilising a keyway, it is recommended using a machine key, as these can be combined excellently due to the manufacturing tolerances.

For a smooth process, it is recommended installing the ball screw with a fixed bearing and a floating bearing. This ensures that the ball screw does not bend due to compression and generate vibrations. For this purpose, MISUMI offers the right support units drives in various designs. For more information on how to install ball screws, see the Installation Instructions available as a PDF.

Ball screw nuts are available in different shapes. These enable versatile utilisation, even in confined spaces. Due to their high precision, the ball screws can also provide a high level of repeatability that is necessary in precise positioning applications. These can be utilised, for example, for measuring devices or in 3D printing. It is recommended to use a pre-stressed ball screw for highly precise applications. Due to the pre-tensioning, the axial play is almost zero unlike a conventional ball screw. In addition, MISUMI offers single axis actuators (locating units) for such applications, which as drives are already equipped with precise ball screws.

In smaller applications, a slide screw or a so-called miniature screw drive can be used. Due to their design, these are very compact, but suitable for lower axial loads.

If very high forces occur, a lead screw could also be considered.

Which ball screw is the right one for your application must be calculated based on the existing factors and influences. You can use the selection Ball Screws that is available as a PDF for this purpose. You can also find the service life calculation in this link.

Application Examples - Ball Screws

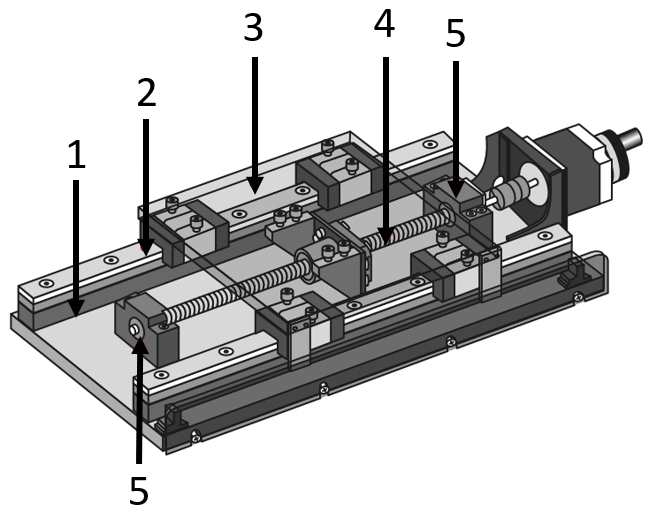

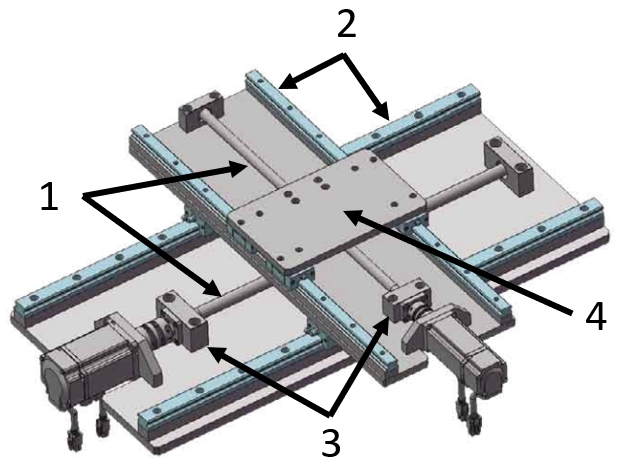

Application example for positioning stages

(1) Linear guide accessories, (2) Standard linear guide, (3) Table plate (meviy), (4) Ball screw, (5) Support units

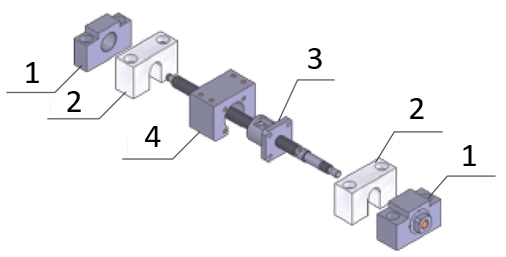

Application example for the ball screw

(1)) Support units, (2) Ball screw nut stops, (3) Ball screw, (4) Ball screw nut mountings

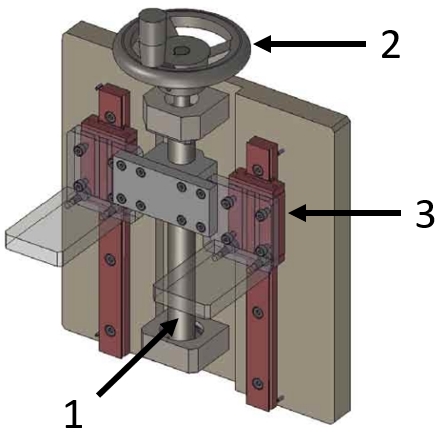

Application example for a lifting device

(1) Ball screw, (2) Standard linear guide, (3) Support units, (4) Table top (meviy)

(1) Ball screw, (2) Standard linear guide, (3) Support units, (4) Table top (meviy)

Industrial Applications

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | RoHS | Accuracy Grade | Screw Shaft O.D. (mm) | Lead (mm) | Axial Play | Number of Circuits (Rows x Windings) | Shaft Overall Length L (mm) | Basic Load Rating Dynamic Rating (N) | Basic Load Rating Static Rating (N) | Grease Type | Shaft End Length F (mm) | Shaft Dia. P (Ø) | Screw Shaft Surface Treatment | Shaft End Dimension (Fixed, Configurable) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 12 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Standard | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 14 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type G | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 14 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type L | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 12 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Standard | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 14 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type G | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 14 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type L | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 12 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Standard | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 14 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type G | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 14 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type L | 15 | 8 | LTBC Plating | Stationary | ||

| 1 | 12 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Standard | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 14 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type G | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 14 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type L | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 12 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Standard | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 14 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type G | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 14 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type L | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 12 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Standard | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 14 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type G | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 14 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type L | 15 ~ 24 | 5 ~ 8 | LTBC Plating | Configuration | ||

| 1 | 7 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Standard | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 9 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type G | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 9 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type L | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 7 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Standard | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 9 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type G | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 9 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type L | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 7 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Standard | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 9 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type G | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 9 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type L | 15 | 8 | Phosphate Coating | Stationary | ||

| 1 | 7 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Standard | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 9 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type G | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 9 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type L | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 7 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Standard | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 9 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type G | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 9 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type L | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 7 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Standard | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 9 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type G | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 9 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type L | 15 ~ 24 | 5 ~ 8 | Phosphate Coating | Configuration | ||

| 1 | 7 Days | 10 | C7 | 12 | 4 | 0.030 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Standard | 15 | 8 | Not Provided | Stationary | ||

| 1 | 9 Days | 10 | C7 | 12 | 4 | 0.030 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type G | 15 | 8 | Not Provided | Stationary | ||

| 1 | 9 Days | 10 | C7 | 12 | 4 | 0.030 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type L | 15 | 8 | Not Provided | Stationary | ||

| 1 | 7 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Standard | 15 | 8 | Not Provided | Stationary | ||

| 1 | 9 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type G | 15 | 8 | Not Provided | Stationary | ||

| 1 | 9 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type L | 15 | 8 | Not Provided | Stationary | ||

| 1 | 7 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Standard | 15 | 8 | Not Provided | Stationary | ||

| 1 | 9 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type G | 15 | 8 | Not Provided | Stationary | ||

| 1 | 9 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type L | 15 | 8 | Not Provided | Stationary | ||

| 1 | 7 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Standard | 15 | 8 | Not Provided | Stationary | ||

| 1 | 9 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type G | 15 | 8 | Not Provided | Stationary | ||

| 1 | 9 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type L | 15 | 8 | Not Provided | Stationary | ||

| 1 | 7 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Standard | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration | ||

| 1 | 9 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type G | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration | ||

| 1 | 9 Days | 10 | C10 | 12 | 4 | 0.05 or Less | 1 x 2.5 | 150 ~ 800 | 2600 | 5800 | Type L | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration | ||

| 1 | 7 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Standard | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration | ||

| 1 | 9 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type G | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration | ||

| 1 | 9 Days | 10 | C10 | 12 | 10 | [0.10 or Less] 0.10 or Less | 1 x 1.5 | 150 ~ 800 | 2850 | 4950 | Type L | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration | ||

| 1 | 7 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Standard | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration | ||

| 1 | 9 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type G | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration | ||

| 1 | 9 Days | 10 | C10 | 14 | 5 | [0.10 or Less] 0.10 or Less | 1 x 2.5 | 150 ~ 800 | 4400 | 7300 | Type L | 15 ~ 24 | 5 ~ 8 | Not Provided | Configuration |

Loading...

Basic information

| Type | Rolled | Nut Type | Standard Nuts | Package Products/Single Item | Set |

|---|---|---|---|---|---|

| Flange Shape | Round Chamfered | Preload | Not Preloaded | Conditions of Use | Standard |

| Twisting Direction | Right | Nut structure | 1-fach | Circuit System | Tube Type |

| Axial End Type | Standard Shaft End Alterations Item | Nut Size | Standard |

Configure

Basic Attributes

-

Accuracy Grade

- C7

- C10

-

Screw Shaft O.D.(mm)

-

Lead(mm)

-

Axial Play

- 0.030 or Less

- 0.10 or Less

- 0.05 or Less

-

Number of Circuits(Rows x Windings)

- 1 x 1.5

- 1 x 2.5

-

Shaft Overall Length L(mm)

-

Grease Type

- Standard

- Type G

- Type L

-

Shaft End Length F(mm)

-

Shaft Dia. P(Ø)

-

Screw Shaft Surface Treatment

- LTBC Plating

- Not Provided

- Phosphate Coating

-

Shaft End Dimension (Fixed, Configurable)

- Configuration

- Stationary

-

Type

- BSRR1204

- BSRR1204G

- BSRR1204L

- BSRR1210

- BSRR1210G

- BSRR1210L

- BSRR1405

- BSRR1405G

- BSRR1405L

- BSRRK1204

- BSRRK1204G

- BSRRK1204L

- BSRRK1210

- BSRRK1210G

- BSRRK1210L

- BSRRK1405

- BSRRK1405G

- BSRRK1405L

- BSSR1204

- BSSR1204G

- BSSR1204L

- BSSR1210

- BSSR1210G

- BSSR1210L

- BSSR1405

- BSSR1405L

- BSSRK1204

- BSSRK1204G

- BSSRK1204L

- BSSRK1210

- BSSRK1210G

- BSSRK1210L

- BSSRK1405

- BSSRK1405G

- BSSRK1405L

- BSST1204

- BSST1204G

- BSST1204L

- BSSZ1204

- BSSZ1204G

- BSSZ1204L

- BSSZ1210

- BSSZ1210G

- BSSZ1210L

- BSSZ1405

- BSSZ1405G

- BSSZ1405L

- BSSZK1204

- BSSZK1204G

- BSSZK1204L

- BSSZK1210

- BSSZK1210G

- BSSZK1210L

- BSSZK1405

- BSSZK1405G

- BSSZK1405L

- c

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 7 Days or Less

- 9 Days or Less

- 12 Days or Less

- 14 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

How do you mount a ball screw drive?

-

Answer:

A ball screw should be stored with a fixed bearing and a floating bearing. The fixed bearing should ideally be installed on the engine side or the drive side. Fixed bearing housings come already equipped with angular contact ball bearings to absorb axial forces. This combination makes ball screws an ideal candidate for positioning. However, a preloaded threaded drive should be selected for very high precision as it has very little axial play.

-

Question:

Why should a fixed and floating bearing be used?

-

Answer:

A fixed bearing housing is often used on the drive side. The floating bearing with housing, on the other hand, allows a small axial deviation and thus compensates for a change in length or a length tolerance. This prevents compression and bending of the ball screw and an imbalance through the length compensation. This may already occur by heating the spindle or application. Fixed and floating bearings are recommended in many rotary applications.

-

Question:

How does a ball screw work?

-

Answer:

A ball screw works similarly to a profile rail guide . In the nut of the ball screw, balls are in a closed ball circulation, which are guided to the spindle by the circular alignment. Thus, an unlimited stroke is theoretically possible, which, however, is limited by the length of the spindle. It is important to ensure that the nut of the ball screw is not removed from the spindle, because the balls can fall out as a result.

-

Question:

Why does the spindle oscillate in a ball screw drive?

-

Answer:

One possible cause for this could be that the ball screw is exposed to excessively high rotational speeds. The permissible rotational speed should not be higher than 80% of the critical speed. Here, attention should be paid not only to the visibly rotating components, but also to the rotational speed of the balls. Further information can be found in the ball screw driver selection as a PDF. Another possibility for the spindle to oscillate could be a compression of the spindle. Therefore, it is important to install a ball screw with a fixed bearing and a floating bearing so that these stresses can be compensated through a floating bearing. MISUMI offers this as ready-to-install bearing housings.

-

Question:

Is the ball screw nut removable?

-

Answer:

The ball screw nut or ball wrap nut should not be removed from the lead screw. There is a risk that the balls will fall out of the nut. This also means that the nut should not be extended over the threaded surface of the spindle. To remove the nut, you can work carefully with a transition shaft with the appropriate core diameter. However, MISUMI also offers an option [TAS] that provides a transition shaft with the ball screw drive. If a ball screw with reverse ball screw is required, the option [RLC] can be supplied with the ball screw nut installed in reverse.

-

Question:

Can you replace just the ball screw nut?

-

Answer:

A ball screw drive should always be replaced as one unit. If damage or wear has already occurred on the spindle, the accuracy of the ball screw drive can no longer be guaranteed. Therefore, it is always recommended replacing spindle and nut together. In addition, the ball screw nut should generally not be removed from the spindle. As a result, the balls that are necessary for the transmission of force may fall out.

-

Question:

How long does a ball screw lasts?

-

Answer:

How long a ball screw can withstand an application depends on many factors. Therefore, it is not possible to say generally how long a ball screw will last. When a ball screw should be replaced, it must be determined mathematically. In the following link, you will find the appropriate calculation formula for the lifetime available as a PDF.

-

Question:

How large is the axial play of a ball screw?

-

Answer:

The axial play varies depending on the precision class and size of the ball screw. You can find the appropriate axial play for different ball screws under the selection Ball Screws available as a PDF .

-

Question:

What must be considered when installing a ball screw?

-

Answer:

When installing a ball screw spindle, more must be taken into account than just ensuring that it is installed tension-free. There are a few things you should observe even before installation. You can view these as a PDF under Precautions.

-

Question:

Are the ball screws lubricated?

-

Answer:

The ball screws from MISUMI are pre-greased. Various lubricants are available for this purpose. Lithium-saponified lubricants are used as standard lubricants. In addition, MISUMI offers heat-resistant lubricants or lubricants suitable for cleanrooms. You can find further information under Installation and Maintenance available as a PDF.

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry