- Stoc

- Afișați numai articolele din stoc

- [M] Diameter (Screw Thread) Nominal

- 5

- [L] Length(mm)

- 12

- Material

- Stainless Steel

- EN 1.4567 Equiv.

- Surface Treatment

- Strength Class (Stainless Steel)

- Application

- Thread Length ℓ(mm)

- Type

- CAD

- 2D

- 3D

- Est. zile de expediere

- Toate

- Expediere în aceeași zi posibilă

Socket head screws / flat head / hexagon socket / steel, stainless steel / burnished / A4-80, A2-50 (CBSST5-12)

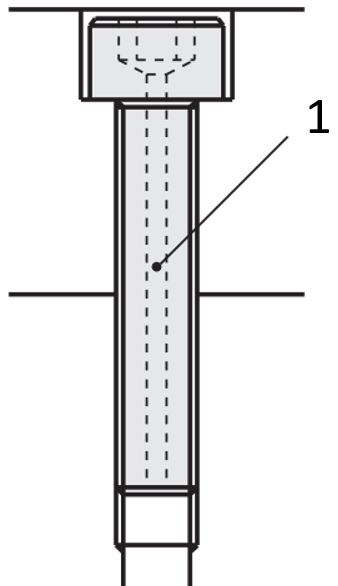

Desen de ansamblu și tabel de specificații

Back to the Category Flat Head Screws/Low Head Screws

Available dimensions and tolerances can be found under the tab More Information.

| Type | [ M ] Material | [ H ] Hardness | [ S ] Surface Treatment | Strength Class |

| CBSH(High Strength) | EN 1.7220 Equiv. | 32~39HRC | Black Oxide | 10.9 |

| CBS | EN 1.1191 Equiv.(M3~8 • M12) EN 1.7220 Equiv.(M10) | 22~32HRC | Black Oxide | 10.9 |

| CBSSTH(High Strength) | EN 1.4404 Equiv. | - | - | A4-80 (8.8 Equiv.) |

| CBSST | EN 1.4567 Equiv. | - | - | A2-50(M2~M2.5) A2-70(M3~M12) |

| BOX-CBSST |

Further specifications can be found under the tab More Information.

| Part Number |

| CBSST4-10 |

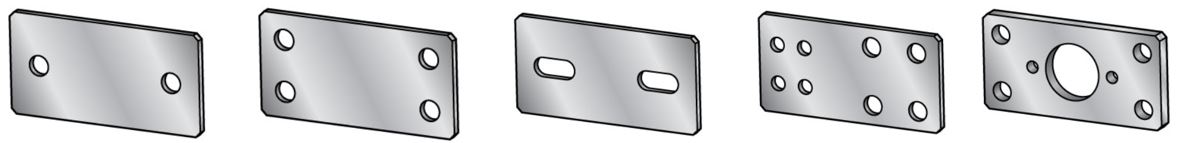

Flathead Screw Selection Details

- Drive: hex (external hex), hexagon socket, hex socket (Torx)

- Strength classes: 8.8, 10.9, A2-50, A4-80

- Threads: M2, M2.5, M2.6, M3, M4, M5, M6, M8, M10, M12

- Thread lengths: 3 mm – 50 mm

- Surface coating: burnished, nickel-plated, chrome-plated, LTBC coating

- Materials: stainless steel, steel

Description/Basics

The screwed connection is one of the most commonly used methods among the soluble compounds. Due to their flat head, flathead screws have various advantages over conventional screws.

Screws with a flat head are often utilised in places that need to form a flat level as much as possible.

Due to their head geometry, flathead screws allow counterbores to be made less deep or completely omitted. This allows covers to be made thinner walls and thus save weight. These advantages also result in cost savings through material savings and the elimination or shortening of production steps. The MISUMI flat-head screws are thus ideal for mounting sheet metal, thin panels, housing covers and other covers.

As opposed to the head form of commercially available screws, the flathead screw reduces the risk of injury at accessible locations, such as housing covers, mounting flaps, etc. This also eliminates the frequently required plastic caps on large screw heads.

Contrary to the standard flathead screws (DIN 921, DIN 922 and DIN 923), MISUMI has flathead screws with hexagon socket, hexagon socket (Torx) and external hexagon. These drive types reduce slipping during assembly compared to typical cross or slotted drives.

MISUMI offers flathead screws in various strength classes.

However, due to the delicate head of flathead screws, the strength on the head can be lower than that on the thread, since there is less material available. The respective strength class is therefore assigned to the individual flathead screws (see Basic Properties).

Areas of Application

Flathead screws are intended for fastening of joining parts. Often, the flathead screws are used for housing covers or in applications requiring low weight.

Thanks to the multi-selectable surface treatments, flathead screws are particularly resistant to environmental influences. This allows flathead screws to be used in almost all industry sectors of plant engineering and mechanical engineering.

The benefits of using flathead screws are versatile. The main advantages of flathead screws are their low weight and space savings.

To utilise a flathead screw with vent function, e.g., for pressure equalization, MISUMI also offers hollow screws with a flat head.

(1) Through-hole for exhaust air

Materials

Strength classes

The strength class gives the tensile strength [R m ] and yield strength [R e ], or expansion limit [R p-0.2] of the screw.

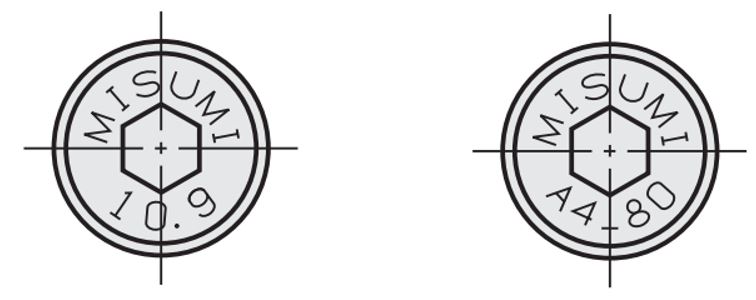

Screws that are subject to a strength class are often marked by the strength class on the screw head. For some screws, the reference to the strength class is missing. In such cases, please refer to the Screw Data Sheet (see Basic Properties).

The screw strength class is an indication of the tensile strength and the expansion limit of a screw. The higher the specification of the strength class, the higher the tensile strength and expansion limit. In principle, a distinction is made between steel and stainless steel (stainless steel).

Stainless steel screws are marked with the letters A, C and F (e.g., A2-50). Steel screws are marked with two numbers, separated by a dot (e.g., 8.8).

The tensile strength and elongation limit can be determined based on this information. Which of the two values and safety number are used for the further calculation of the screws depends on the applied load case.

Example of a strength marking

Tensile strength steel

Example: 8.8

R m = 8 x 100 N/mm 2 = 800 N/mm 2

The expansion limit of the screw material is the resistance value that can be applied to the material without permanent deformation. Thus, the screw can return to its original length after this stress (elastic range).

If the elastic range is exceeded, there is a permanent (plastic) deformation, which can end in a tear/fracture of the material upon further stress.

To determine the value, both values of the strength specification are multiplied with each other and additionally by a factor of 10.

Example 8.8

R p-0.2 = 8 x 8 x 10 N/mm 2 = 640N /mm 2

Tensile strength stainless steel

For stainless steel screws, the strength specification begins with the specification of the material group used.

The most common stainless steel screw is the A2 stainless steel screw, which is manufactured from (colloquially speaking) V2A material. In this example, the A2 screw is made of austenitic stainless steel.

Ferritic stainless steel screws are often marked with a [F] at the beginning and martensitic stainless steel types with a [C].

Unlike the steel screws, the second value of the strength specification is multiplied by a factor of 10 for the stainless steel screws in order to determine the tensile strength of the screw material. The expansion limit [R p-0.2] must be determined in tabular form based on the expansion limit of the raw material or the manufacturer.

Example A2-50

R m = 50 x 10 N/mm 2 = 500 N/mm 2

Screws without specification of this strength classification have manufacturer-bound values that must be taken from the respective data sheets or manufacturer information. This often occurs with screws with special shape and treatment.

Coatings

MISUMI’s flathead screws are available in burnished, chrome-plated, or nickel-plated to best protect them from corrosion.

As an alternative to one of these surface treatments, flathead screws can also be coated with LTBC. The LTBC coating (Low Temperature Black Chrome Platinum) is a surface coating that protects against corrosion and has low reflection. The coating consists of a 5 μm thick chrome ceramic layer with fluoropolymer infusion and forms a black film. In addition, the LTBC coating is resistant to cracking and bending and it is thus resistant to peeling due to extreme or repeated bending. This makes LTBC-coated flathead screws particularly suitable for areas where corrosion or light reflections are undesirable.

Dimensions

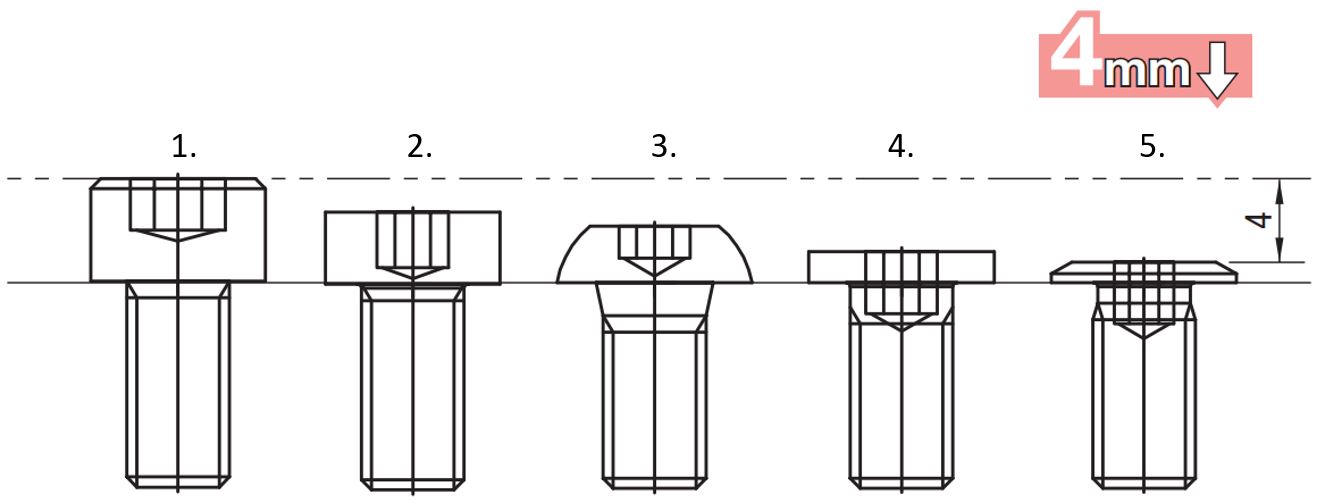

Compared to an M5 standard cylinder head screw with 5 mm head height, with a flathead screw it is possible to save up to 4 mm of head height.

(1) Standard cylinder head screws, (2) Flat head, (3) Safety screws, (4) Very flat head, (5) Ultra flat head

| Products | Hexagon socket screws | flat head | Safety screws | very flat head | ultra flat head | |

|  |  |  |  | ||

| P. 172, 174, 175 | P. 194 | P. 185 | P. 195 | P. 196 | ||

| Head height (in mm) | ||||||

| M | 2 | 2 | 1.3 | 1.3 | 1.1 (min.*) | 0.5 |

| 2.5 | 2.5 | 1.6 | 1.5 | 1.3 (min.*) | 0.6 | |

| 3 | 3 | 2 | 1.65 | 1.5 | 0.8 | |

| 4 | 4 | 2.8 | 2.2 | 1.5 | 0.9 | |

| 5 | 5 | 3.5 | 2.75 | 1.5 | 1 | |

| 6 | 6 | 4 | 3.3 | 1.5 | 1.2 | |

| 8 | 8 | 5 | 4.4 | 1.5 | - | |

| 10 | 10 | 6 | 5.5 | 1.5 | - | |

| 12 | 12 | 7 | - | - | - | |

Bolt Head Height Comparison Chart

*Head height varies by material.

Tightening torques/torques

| Products | flat head | very flat head | ultra flat head | |||||

| Steel | Steel, stainless steel | Stainless steel | Steel | Stainless steel | Steel | Steel | ||

| Strength class | 10.9 | 8.8, A4-80 | A2-50 | 5.8 (M10, 4.8) | - | - | - | |

| Tensile strength (N/mm 2) | 1040 | 800 | 500 | 500 (M10, 400) | 400 | 350 (M2, 200) | 350 (M2, 200) | |

| M | 2 | - | - | 0.25 | 0.25 | 0.25 | 0.16 | 0.178 |

| 2.5 | - | - | 0.42 | 0.82 | 0.42 | 0.35 | - | |

| 3 | 1.1 | 0.9 | 0.8 | 0.9 | 0.8 | 0.6 | 0.63 | |

| 4 | 4.0 | 1.8 | 1.6 | 1.8 | 1.6 | 1.1 | 1.5 | |

| 5 | 6.1 | 3.6 | 3.2 | 3.2 | 3.0 | 2.2 | 3.0 | |

| 6 | 10.5 | 7.2 | 6.5 | 5.2 | 5.0 | 5.0 | 5.2 | |

| 8 | 18.4 | 10.8 | 9.7 | 9.0 | 8.6 | - | - | |

| 10 | - | 31.5 | 28.4 | 16.2 | 15.4 | - | - | |

| 12 | - | 45.0 | 40.5 | - | - | - | - | |

Note: The above values are for comparison purposes only (reference values).

Further specifications can be found under the tab More Information.

Installation Information

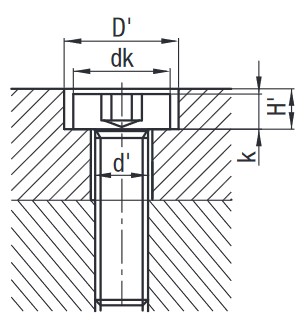

Dimensions of the screw and counterbores

| Thread (d) | flat head | very flat head (stainless steel screw) | ultra flat head Hexagon socket | ultra flat head Torx | ||||||||||||||||

| d' | dk | D' | k | H' | d' | dk | D' | k | H' | d' | dk | D' | k | H' | d' | dk | D' | k | H' | |

| M2 | 2.5 | 3.8 | 5 | 1.3 | 1.5 | 4 | 4 | 5 | 1.1 (1.5) | 1.3 (1.7) | 2.5 | 4 | 5 | 0.5 | 0.7 | 2.5 | 4 | 5 | 0.5 | 0.7 |

| M2.5 | 3 | 4.5 | 5.5 | 1.6 | 1.8 | 3 | 5 | 6 | 1.3 (1.5) | 1.5 (1.7) | 3 | 5 | 6 | 0.6 | 0.8 | - | - | - | - | - |

| M3 | 3.5 | 5.5 | 6.5 | 2 | 2.3 | 3.5 | 6 | 7 | 1.3 (1.5) | 1.6 (1.8) | 3.5 | 6 | 7 | 0.8 | 1.1 | 3.5 | 7 | 8 | 0.8 | 1.1 |

| M4 | 4.5 | 7 | 8 | 2.8 | 3.2 | 4.5 | 8 | 9 | 1.5 | 1.9 | 3.4 | 8 | 9 | 1.1 | 1.3 | 4.5 | 8 | 9 | 0.9 | 1.3 |

| M5 | 5.5 | 8.5 | 9.5 | 3.5 | 3.9 | 5.5 | 9 | 10 | 1.5 | 1.9 | 5.5 | 9 | 10 | 1.4 | 1.4 | 5.5 | 9 | 10 | 1 | 1.4 |

| M6 | 6.5 | 10 | 11 | 4 | 4.5 | 6.5 | 10 | 11 | 1.5 | 2 | 6.5 | 10 | 11 | 1.7 | 1.7 | 6.5 | 12 | 13 | 1.2 | 1.7 |

| M8 | 9 | 13 | 14 | 5 | 5.6 | 9 | 13 | 14 | 1.5 | 2.1 | - | - | - | - | - | - | - | - | - | - |

| M10 | 11 | 16 | 17.5 | 6 | 6.8 | 11 | 16 (15) | 17.5 (16.5) | 1.5 | 2.3 | - | - | - | - | - | - | - | - | - | - |

| M12 | 14 | 18 | 20 | 7 | 8 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Further specifications can be found under the tab More Information.

Informații detaliate

Desen de ansamblu și specificații

Back to the Category Flat Head Screws/Low Head Screws

| MxP | A | E | B | t max. | r |

| 2x0.4 | 3.8 | 1.3 | 1.3 | 1 | 0.1 or More |

| 2.5x0.45 | 4.5 | 1.6 | 1.5 | 1.3 | 0.1 or More |

| 3x0.5 | 5.5 | 2 | 2 | 1.5 | 0.1 or More |

| 4x0.7 | 7 | 2.8 | 2.5 | 2.3 | 0.2 or More |

| 5x0.8 | 8.5 | 3.5 | 3 | 2.7 | 0.2 or More |

| 6x1.0 | 10 | 4 | 4 | 3 | 0.25 or More |

| 8x1.25 | 13 | 5 | 5 | 3.8 | 0.4 or More |

| 10x1.5 | 16 | 6 | 6 | 4.5 | 0.4 or More |

| 12x1.75 | 18 | 7 | 8 | 5 | 0.6 or More |

■ Available in Single item

| Part Number | ℓ | Unit Price | |||||

| Type | M-L | CBSH | CBSSTH | CBSH | CBS | CBSSTH | CBSST |

| CBS | CBSST | ||||||

| CBSST | 2-4 | - | Studs - Fully Threaded | - | - | - | |

| 5 | |||||||

| 6 | |||||||

| 2.5-4 | - | Studs - Fully Threaded | - | - | - | ||

| 5 | |||||||

| 6 | |||||||

| 8 | |||||||

| 10 | |||||||

| CBSH CBS CBSSTH CBSST | 3-4 | Studs - Fully Threaded | Studs - Fully Threaded | - | - | ||

| 5 | |||||||

| 6 | |||||||

| 8 | |||||||

| 10 | |||||||

| 12 | - | ||||||

| 16 | - | ||||||

| 20 | 12 | ||||||

| 4-5 | Studs - Fully Threaded | Studs - Fully Threaded | - | ||||

| 6 | |||||||

| 8 | |||||||

| 10 | |||||||

| 12 | |||||||

| 16 | - | - | |||||

| 20 | |||||||

| 25 | |||||||

| 5-5 | Studs - Fully Threaded | Studs - Fully Threaded | - | - | - | ||

| 6 | |||||||

| 8 | |||||||

| 10 | |||||||

| 12 | |||||||

| 16 | |||||||

| 20 | - | - | |||||

| 25 | |||||||

| 30 | 16 | 22 | |||||

| 6-8 | Studs - Fully Threaded | Studs - Fully Threaded | - | - | |||

| 10 | |||||||

| 12 | |||||||

| 16 | |||||||

| 20 | |||||||

| 25 | - | - | |||||

| 30 | 18 | ||||||

| 35 | 24 | ||||||

| 40 | |||||||

| 45 | |||||||

| CBSH CBS CBSST | 8-10 | Studs - Fully Threaded | Studs - Fully Threaded | - | - | ||

| 12 | |||||||

| 16 | |||||||

| 20 | |||||||

| 25 | |||||||

| 30 | - | ||||||

| 35 | 22 | ||||||

| 40 | 28 | ||||||

| 45 | |||||||

| 50 | |||||||

| Part Number | ℓ | Unit Price | |||

| Type | M-L | CBS | CBSST | CBS | CBSST |

| CBS CBSST | 10-16 | Studs - Fully Threaded | Studs - Fully Threaded | ||

| 20 | |||||

| 25 | |||||

| 30 | |||||

| 35 | |||||

| 40 | |||||

| 45 | 32 | 36 | |||

| 50 | |||||

| 12-20 | Studs - Fully Threaded | Studs - Fully Threaded | |||

| 25 | |||||

| 30 | |||||

| 35 | |||||

| 40 | |||||

| 45 | |||||

| 50 | 30 | 40 | |||

■ Box

| Part Number | ℓ | Unit Price | Pcs./ Box. | ||

| Type | M-L | Price per pkg. | 1 Box | ||

| BOX-CBSST (Stainless Steel) | 3-6 | Studs - Fully Threaded | 1000 pcs./Box | ||

| 8 | |||||

| 10 | |||||

| 12 | |||||

| 16 | |||||

| 20 | |||||

| 4-6 | Studs - Fully Threaded | 1000 pcs./Box | |||

| 8 | |||||

| 10 | |||||

| 12 | |||||

| 16 | |||||

| 20 | 500 pcs./box | ||||

| 5-8 | Studs - Fully Threaded | ||||

| 10 | |||||

| 12 | |||||

| 16 | |||||

| 20 | |||||

| 6-8 | Studs - Fully Threaded | 500 pcs./box | |||

| 10 | |||||

| 12 | |||||

| 16 | |||||

| 20 | 300 pcs./box | ||||

| 25 | |||||

| 8-10 | Studs - Fully Threaded | 300 pcs./box | |||

| 12 | |||||

| 16 | 250 pcs./box | ||||

| 20 | 200 pcs./box | ||||

| 25 | |||||

| 30 | 150 pcs./box | ||||

■Mechanical Properties (Reference)

| Type | Tensile Strength (N/mm2) | 0.2% Proof Stress (N/mm2) | Corrosion Resistance | Nonmagnetic |

| CBSH | 1040 | 900 | △ | × |

| CBS | 800 | 640 | △ | × |

| CBSSTH | 800 | 640 | ◎ | ◎ |

| CBSST | 500 | 210 | ○ | ○ |