Confirmat

- Single Angle (θ)(Degree)

- 1

- Flute Length (ℓ)(mm)

- 30

- R Size(mm)

- 1

- Shank Diameter (d)(mm)

- 4

- Overall Length (L)(mm)

- 70

- Type

- Est. zile de expediere

- Toate

- În 5 zile lucrătoare

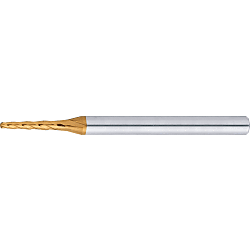

TSC series carbide tapered ball end mill, 4-flute / long model (TSC-TBEM4LB1-1-30)

Desen de ansamblu

Informații detaliate

Informații de bază

(Select the shortest possible blade length to maintain rigidity)

-It has a coating with high oxidation resistance and high hardness, and achieves long life. Effective in high-speed machining and dry machining as coating properties

-Can be reground. Please refer to the "Regrinding Service" page for application procedures, performance range, prices, etc.

Specificații și preț

Specifications

| Model Number | Large Tip Diameter D1 |

Overall Length L |

Shank Diameter d |

|||

| Tip R |

Single Angle θ |

Flute Length ℓ |

||||

| TSC-TBEM4LB | 0.3 | 0.5° | 4 | 0.66 | 45 | 4 |

| 6 | 0.7 | 45 | 4 | |||

| 1° | 4 | 0.73 | 45 | 4 | ||

| 6 | 0.8 | 45 | 4 | |||

| 2° | 4 | 0.86 | 45 | 4 | ||

| 6 | 1 | 45 | 4 | |||

| 0.4 | 0.5° | 6 | 0.9 | 50 | 4 | |

| 8 | 0.93 | 50 | 4 | |||

| 1° | 6 | 1 | 50 | 4 | ||

| 8 | 1.07 | 50 | 4 | |||

| 1.5° | 6 | 1.09 | 50 | 4 | ||

| 8 | 1.2 | 50 | 4 | |||

| 2° | 6 | 1.19 | 50 | 4 | ||

| 8 | 1.33 | 50 | 4 | |||

| 0.5 | 0.5° | 10 | 1.17 | 50 | 4 | |

| 12 | 1.2 | 50 | 4 | |||

| 16 | 1.27 | 60 | 4 | |||

| 1° | 10 | 1.33 | 50 | 4 | ||

| 12 | 1.4 | 50 | 4 | |||

| 16 | 1.54 | 60 | 4 | |||

| 1.5° | 10 | 1.5 | 50 | 4 | ||

| 12 | 1.6 | 50 | 4 | |||

| 16 | 1.81 | 60 | 4 | |||

| 2° | 10 | 1.66 | 50 | 4 | ||

| 12 | 1.8 | 50 | 4 | |||

| 16 | 2.08 | 60 | 4 |

| Model Number | Large Tip Diameter D1 |

Overall Length L |

Shank Diameter d |

|||

| Tip R |

Single Angle θ |

Flute Length ℓ |

||||

| TSC-TBEM4LB | 0.75 | 0.5° | 10 | 1.66 | 50 | 4 |

| 12 | 1.7 | 50 | 4 | |||

| 16 | 1.77 | 60 | 4 | |||

| 1° | 10 | 1.82 | 50 | 4 | ||

| 12 | 1.89 | 50 | 4 | |||

| 16 | 2.03 | 60 | 4 | |||

| 1.5° | 10 | 1.98 | 50 | 4 | ||

| 12 | 2.09 | 50 | 4 | |||

| 16 | 2.3 | 60 | 4 | |||

| 2° | 10 | 2.15 | 50 | 4 | ||

| 12 | 2.29 | 50 | 4 | |||

| 16 | 2.57 | 60 | 4 | |||

| 1 | 0.5° | 10 | 2.16 | 50 | 4 | |

| 20 | 2.33 | 60 | 4 | |||

| 30 | 2.51 | 70 | 4 | |||

| 1° | 10 | 2.31 | 50 | 4 | ||

| 20 | 2.66 | 60 | 4 | |||

| 30 | 3.01 | 70 | 4 | |||

| 1.5° | 10 | 2.47 | 50 | 4 | ||

| 20 | 3 | 60 | 4 | |||

| 30 | 3.52 | 70 | 4 | |||

| 2° | 10 | 2.63 | 50 | 4 | ||

| 20 | 3.33 | 60 | 4 | |||

| 30 | 4.03 | 70 | 4 | |||

| 1.25 | 0.5° | 10 | 2.65 | 50 | 4 | |

| 20 | 2.83 | 60 | 4 | |||

| 30 | 3 | 70 | 4 | |||

| 1° | 10 | 2.81 | 50 | 4 | ||

| 20 | 3.15 | 60 | 4 | |||

| 30 | 3.5 | 70 | 4 | |||

| 1.5° | 10 | 2.96 | 50 | 4 | ||

| 20 | 3.48 | 60 | 4 | |||

| 30 | 4.01 | 70 | 4 | |||

| 2° | 10 | 3.11 | 50 | 4 | ||

| 20 | 3.81 | 60 | 4 | |||

| 30 | 4.51 | 70 | 6 |

For Cutting Conditions, Refer to >>Click here.

Caracteristici și exemple de utilizare

More Information

● Has a new TS film coating with much greater oxidation resistance and hardness than conventional films, yielding a longer operational life and ideal for high-speed machining / dry machining.

● A blade length can be selected to match the rib groove depth. (Select a bit with a blade length as short as possible in order to retain rigidity)

Codul de piesă a fost confirmat