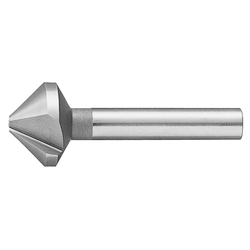

Centering/Countersink (Coating Type: Non-Coated)

ATOM

3.175 mm Shank for Pointing Drill Tip 120° Steel

Drill dedicated for guide holes for micro-diameter machining. Ideal for machining where it is difficult to ensure the hole position and hole diameter precision. Added small diameter sizes from φ0.03 to φ0.3 in 0.01 mm incrementsCitiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) / Drilling 120 0.03 ~ 3 General Steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] Single blade Available Carbide N/A Non-Coated ConfigurarePreț normal (fără TVA):55.79 €~Dată de expediere normală:6 zile lucrătoare

- Volume Discount

NAKAJIMAKOUKI

Center Drill, Okabe Standard, JIS Type 1 60°

As it is made of high speed steel, it has a high hardness. It is a centre drill made with one of the best heat treatments, making it suitable for machining general steel.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) 60 0.7 ~ 6 General Steel[○] Double-edged N/A High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):15.69 €~Dată de expediere normală:6 zile lucrătoare

- Volume Discount

NAKAJIMAKOUKI

Center Drill, Okabe Standard, Long Center Drill 60°

As it is made of high speed steel, it has a high hardness. It is a centre drill made with one of the best heat treatments, making it suitable for machining general steel.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) 60 1 ~ 5 General Steel[○] Double-edged N/A High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):58.87 €~Dată de expediere normală:6 zile lucrătoare

- Volume Discount

MISUMI

TiN Coated / Non-Coated High-Speed Steel NC Spot Drill

Long service life that's made possible by the coating technology. Ideal for Hole Chamfering and CenteringCitiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) / Hole Chamfer 90 ~ 120 2 ~ 20 General Steel[○] Single blade N/A Cobalt HSS N/A Non-Coated ConfigurarePreț normal (fără TVA):9.22 €~Dată de expediere normală:5 zile lucrătoare

ILIX

Counter Sink Set Non-Cut 6-Piece【6 bucăți】

Suitable for chamfering, countersinking, and deburring. Housed in a metal case to select the size commonly used. Comes with a handle which enables manual operations.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 90 6.3,8.3,10.4,12.4,16.5,20.5 General Steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] / Resin[○] Single blade Available High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):253.83 €Dată de expediere normală:6 zile lucrătoare

- DISCOUNT

ILIX

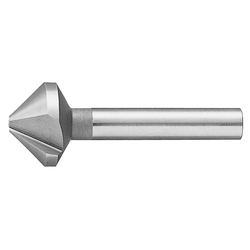

Straight Shank, Countersink, HSS, No Coating 60°

Ideal for chamfering, countersinking, and deburring. Can be used for both machine work and manual work.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 60 6.3 General Steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] / Resin[○] Single blade Available High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):29.48 €Preț normal (fără TVA):Preț specialDată de expediere normală:Articol în stoc - 1 zi lucrătoareExpediere în aceeași zi posibilă

ATOM

3 mm Shank for Pointing Drill Tip 120° Steel

Drill dedicated for guide holes for micro-diameter machining. Ideal for machining where it is difficult to ensure the hole position and hole diameter precision. Added small diameter sizes from φ0.03 to φ0.3 in 0.01 mm incrementsCitiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) / Drilling 120 0.02 ~ 2.5 General Steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] Single blade Available Carbide N/A Non-Coated ConfigurarePreț normal (fără TVA):55.79 €~Dată de expediere normală:6 zile lucrătoare

ATOM

3 mm Shank for Pointing Drill Tip 120° Non-Ferrous / Resin

Drill dedicated for guide holes for micro-diameter machining. Ideal for machining where it is difficult to ensure the hole position and hole diameter precision. Added small diameter sizes from φ0.03 to φ0.3 in 0.01 mm incrementsCitiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) / Drilling 120 0.03 ~ 3 Aluminum[◎] / Resin[◎] Single blade Available Carbide N/A Non-Coated ConfigurarePreț normal (fără TVA):50.86 €~Dată de expediere normală:6 zile lucrătoare

- DISCOUNT

ATOM

3 mm Shank for Pointing Drill Tip 90° Steel

Drill dedicated for guide holes for micro-diameter machining. Ideal for machining where it is difficult to ensure the hole position and hole diameter precision. Added small diameter sizes from φ0.03 to φ0.3 in 0.01 mm incrementsCitiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) / Drilling 90 2.1 General Steel[○] / Quenched and tempered steel[○] Single blade Available Carbide N/A Non-Coated ConfigurarePreț normal (fără TVA):52.07 €Preț normal (fără TVA):Preț specialDată de expediere normală:Articol în stoc - 1 zi lucrătoareExpediere în aceeași zi posibilă

SKC

Electric drill / impact screwdriver / drilling machine can also be used.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 90 8 ~ 16 - Single blade Available High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):13.59 €~Dată de expediere normală:6 zile lucrătoare

- DISCOUNT

- Volume Discount

NAKAJIMAKOUKI

As it is made of high speed steel, it has a high hardness. It is a centre drill made with one of the best heat treatments, making it suitable for machining general steel.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) 60 0.5 General Steel[○] Double-edged N/A High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):20.27 €Preț normal (fără TVA):Preț specialDată de expediere normală:Articol în stoc - 1 zi lucrătoareExpediere în aceeași zi posibilă

NAKAJIMAKOUKI

Center Drill, Okabe Standard, Type 1, Carbide 60°

As it is made of carbide, it has both high hardness and high elasticity. It is a centre drill made with one of the best heat treatments and can be used for machining general steel, heat-treated steel, stainless steel, cast iron, etc.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) 60 0.3 ~ 6 General Steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Single blade / Double-edged N/A Carbide N/A Non-Coated ConfigurarePreț normal (fără TVA):117.72 €~Dată de expediere normală:6 zile lucrătoare

NAKAJIMAKOUKI

Center Drill, Okabe Standard, Type 1, Carbide 90°

Since it is made of carbide, it has high hardness and elasticity. It is a centre drill made with one of the best heat treatments and can be used for machining general steel, heat treated steel, stainless steel, cast iron, etc.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) 90 0.3 ~ 6 General Steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Double-edged N/A Carbide N/A Non-Coated ConfigurarePreț normal (fără TVA):103.52 €~Dată de expediere normală:7 zile lucrătoare

- Volume Discount

NAKAJIMAKOUKI

Center Drill, Okabe Standard, R Type R

[Features] -A centre drill manufactured by tempering with one of the best heat treatment-Tip angle: 60°-Drill diameter: 2.5 mm・ Overall length: 53 mm・ Working material: General steel-Tool material: High Speed Steel-Coating / Surface Treatment: Uncoated-Single Edge / Double Edge: Double Edge-Peripheral Edge Yes/No: No-Slot Length: 7.5 mm-Body Diameter: 8 mm.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) 60 2.5 General Steel[○] Double-edged N/A High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):37.54 €Dată de expediere normală:6 zile lucrătoare

- DISCOUNT

- Volume Discount

NAKAJIMAKOUKI

Center Drill, Okabe Standard, Long Center Drill 90°

As it is made of high speed steel, it has a high hardness. It is a centre drill made with one of the best heat treatments, making it suitable for machining general steel.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) 90 1 ~ 5 General Steel[○] Double-edged N/A High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):58.74 €~Preț normal (fără TVA):Preț specialDată de expediere normală:Articol în stoc - 1 zi lucrătoareUnele articole pot fi expediate în aceeași zi

- DISCOUNT

- Volume Discount

NAKAJIMAKOUKI

Center Drill, Okabe Semi-Standard, Type 1 90°

[Features] -A centre drill manufactured by tempering with one of the best heat treatment-Tip angle: 90°-Drill diameter: 1. 8 mm・ Overall length: 47 mm・ Work material: General steel-Tool material: High speed steel-Coating / surface treatment: Uncoated-Single edge / Double edge: Double edge-Peripheral edge Yes/No: No-Flute length: 2.3 mm-Body diameter: 8 mm.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Centering (Positioning) 90 3.2 General Steel[○] Double-edged N/A High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):25.20 €Preț normal (fără TVA):Preț specialDată de expediere normală:Articol în stoc - 1 zi lucrătoareExpediere în aceeași zi posibilă

DIJET

Solid Center Drill CDL / S-CDL Type

[Features] Drill with excellent abrasion resistance.[Features] Suitable for drilling general steel, cast iron and aluminium.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Drilling 60 ~ 90 2 ~ 5 General Steel[○] / Cast Iron[◎] / Aluminum[○] Double-edged - Carbide N/A Non-Coated ConfigurarePreț normal (fără TVA):147.86 €~Dată de expediere normală:8 zile lucrătoare

- DISCOUNT

- Volume Discount

TAIYO-TOOL

3-Blade Chamfering Cutter 3MC (SKH51)

[Applications]· Hole chamfer[Single Blade / Double Blade]· Single blade[Tool Grade]· High-speed steel[Coating Y/N] N[Coating Type] Non-CoatedCitiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 60 ~ 120 16 ~ 46 - Single blade - High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):67.47 €~Preț normal (fără TVA):Preț specialDată de expediere normală:Articol în stoc - 1 zi lucrătoareUnele articole pot fi expediate în aceeași zi

TAIYO-TOOL

Carbide Solid Countersink 3-Flute C-3MC (NF15)

[Applications]· Hole chamfer[Single Blade / Double Blade]· Single blade[Tool Grade]· Carbide[Coating Y/N] N[Coating Type] Non-Coated[Flute No.] 3-FluteCitiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 60 ~ 120 6.3 ~ 25 - Single blade - Carbide N/A Non-Coated ConfigurarePreț normal (fără TVA):243.68 €~Dată de expediere normală:6 zile lucrătoare

DIXI

[Features]· Enables positioning and chamfering with only one process.· Enables high precision positioning (center gouging), accurate positioning on curved and sloped surfaces, and high-quality chamfering (countersink).· High-speed high feed is possible.· Centering and chamfering are done simultaneously before tap pilot hole drilling.[Applications]· Work materials: Steel, alloy steel, stainless steel, cast iron, aluminum, copper, brass, plastic (nylon).[Material]· Carbide alloy (K20)Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type - 90 ~ 120 - - Single blade - - - Non-Coated ConfigurarePreț normal (fără TVA):67.83 €~Dată de expediere normală:6 zile lucrătoare

NOGAJAPAN

[Features]· Countersink carbide blade, suitable for high-hardness quenched steel.[Applications]· Work materials: 1,000 N/mm² or higher high hardness steel and 240 HB or higher gray cast iron, etc.[Specifications]· 3-Flute[Material]· Carbide (K20)Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type - 90 6.3 ~ 31 - - - - - Non-Coated ConfigurarePreț normal (fără TVA):232.92 €~Dată de expediere normală:6 zile lucrătoare

- DISCOUNT

WATERMILLS

WATERMILLS ® 3-Flute Countersink WMC 90° High-Speed Steel

[Features]· 3-flute type.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 90° 10.4 - Single blade - High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):23.13 €Preț normal (fără TVA):Preț specialDată de expediere normală:Articol în stoc - 1 zi lucrătoareExpediere în aceeași zi posibilă

WATERMILLS

WATERMILLS ® 3-Flute Countersink WMC 90° High-Speed Steel, Long Shank Type

[Features] -It has 3 grooves.Applications: Hole chamferingTip angle (θ): 90°Coating type: uncoated.Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 90° 6.3 ~ 25 - Single blade - High-speed steel N/A Non-Coated ConfigurarePreț normal (fără TVA):77.03 €~Dată de expediere normală:7 zile lucrătoare

- DISCOUNT

WATERMILLS

WATERMILLS ® 3-Flute Manual Countersink WMHC 90° with Handle

[Material]· 5% Cobalt HSS SteelCitiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 90° 20.5 - Single blade - Cobalt HSS N/A Non-Coated ConfigurarePreț normal (fără TVA):58.93 €Preț normal (fără TVA):Preț specialDată de expediere normală:Articol în stoc - 1 zi lucrătoareExpediere în aceeași zi posibilă

WATERMILLS

WATERMILLS ® 1-Flute Countersink WMSFC 90° for Drill, Chamfer, for Veneer

[Material] 5% cobalt high speed steelApplications: Hole chamferTip angle (θ): 90°Coating type: uncoatedTotal length (mm): 78 (±).Citiți mai multApplication Tip angle (θ) Tool Diameter (D)(mm) work material Single blade, two blades Peripheral Blade Y/N Tool Material Type Coating Y/N Coating Type Hole Chamfer 90° 25.0(+0.3) - Single blade - Cobalt HSS N/A Non-Coated ConfigurarePreț normal (fără TVA):75.41 €Dată de expediere normală:5 zile lucrătoare