R+W Shaft Couplings(Allowable Torque Range:10.01 to 20.00)

Narrow search by specifying Type

-

With Slit

With Slit -

Disc Type

Disc Type -

Oldham Type

Oldham Type -

Jaw Type

Jaw Type -

Bellows Type

Bellows Type -

Others

Others -

Vibration Damping Rubber Type

Vibration Damping Rubber Type

?* Information on days to ship and prices

-

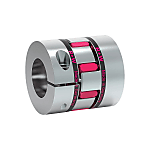

Claw couplings / Hub clamping / Claw disc: PU / Body: aluminium, steel / EKL / R+W ANTRIEBSELEMENTE

R+W

Design

· Two concentrically machined hubs with curved jaws and one clamping screw on each side

Material

· Hubs:

up to 450 series – high-strength aluminum

from series 800 – steel

· Elastomer insert: wear-resistant thermally stable TPU

Temperature range

· Depending on elastomer insert

Features

· Short overall length

· Easy mounting

· Vibration dampingMin. Shipping Days : 13 Days -

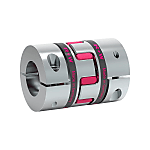

Claw couplings / grub screw clamping, feather key DIN 6885 / claw disc: PU / body: aluminium, steel / EK1 / R+W ANTRIEBSELEMENTE

R+W

Design

· Two concentriclly machined hubs with curved jaws, keyways and set screws

· From series 2500 elastomer insert consists of five individual segments

Material

· Hubs:

up to 450 series – high-strength aluminum

from series 800 – steel

from series 2500 – GGG40

· Elastomer insert: wear-resistant thermally stable TPU

Temperature range

· Depending on elastomer insert

Features

· Low-priced

· High concentricity

· Low backlash (keyway)Min. Shipping Days : 13 Days -

Bellow couplings / grub screw clamping / bellows: stainless steel, TOMBAK / body: aluminium / MK1 / R+W ANTRIEBSELEMENTE

R+W

Design

· Two hubs with radial set screws concentrically mounted to flexible bellows

· Speeds up to 20,000 rpm; over 20,000 with finely balanced version

Material

· Bellows:

from series 0,5 – tombac

from series 1 – high grade stainless steel

· Hubs: aluminum

Temperature range

· -30 °C to +100 °C (-22 °F to +212 °F)

Features

· Integrated dismounting groove

· Low-cost design

· Low moment of inertiaMin. Shipping Days : 17 Days -

Bellow couplings / hub clamping / bellows: stainless steel / body: aluminium / MK2 / R+W ANTRIEBSELEMENTE

R+W

Design

· Two clamping hubs concentrically mounted to flexible bellows

Material

· Bellows: high grade stainless steel

· Hubs: aluminium

Temperature range

· -30 °C to +100 °C (-22 °F to +212 °F)

Features

· Frictional connection

· For highly dynamic applications

· Low moment of inertiaMin. Shipping Days : 17 Days -

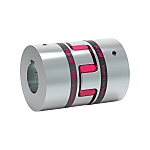

Claw couplings / Hub clamping / Claw disc: PU / Body: aluminium, steel / EK2 / R+W ANTRIEBSELEMENTE

R+W

Design

· Two concentrically machined hubs with curved jaws and one clamping screw on each side

Material

· Hubs:

up to 450 series – high-strength aluminum

from series 800 – steel

· Elastomer insert: wear-resistant thermally stable TPU

Temperature range

· Depending on elastomer insert

Features

· Easy mounting

· High concentricity

· Vibration dampingMin. Shipping Days : 13 Days -

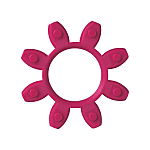

Flexible Shaft Coupling Accessories - EK Series Elastomer Inserts

R+W

The equalizing element of the EK coupling is the elastomer insert. It transmits torque without backlash or vibration. The elastomer insert defines the characteristics of the entire drive system.

Backlash is eliminated by the press fit of the elastomer into the hubs. Through variation of the Shore hardness of the elastomer insert, the coupling system can be optimized for the ideal torsional characteristics.Starting from∗ : 6.59 € Min. Shipping Days : 12 Days *Unit price with basic configuration

| Brand |

|---|

| Product Series |

| Starting from∗ |

| Min. Shipping Days : |

| Type |

| Allowable Misalignment |

| Application |

| Allowable Torque Range(N•m) |

| Shaft Bore Dia. (machined) D1(mm) |

| Shaft Bore Dia. (machined) D2(mm) |

| Outer Dia. A(mm) |

| Overall Length W(mm) |

| Max. Rotational Speed Range(r/min) |

| Feature |

| Body Material |

| Category |

| Allowable Torque(Nm) |

| Max. Rotational Speed(r/min) |

| Allowable Lateral Misalignment Range(mm) |

| Allowable Lateral Misalignment(mm) |

| Allowable Angular Misalignment(deg) |

| Buffer Part Material |

| Disc Part Material |

| Bellows Part Material |

| Brand | R+W | R+W | R+W | R+W | R+W | R+W |

|---|---|---|---|---|---|---|

| Product Series | Claw couplings / Hub clamping / Claw disc: PU / Body: aluminium, steel / EKL / R+W ANTRIEBSELEMENTE | Claw couplings / Hub clamping / Claw disc: PU / Body: aluminium, steel / EK2 / R+W ANTRIEBSELEMENTE | Flexible Shaft Coupling Accessories - EK Series Elastomer Inserts | |||

| Starting from∗ | - | - | - | - | - | 6.59 € *Unit price with basic configuration |

| Min. Shipping Days : | 13 Days | 13 Days | 17 Days | 17 Days | 13 Days | 12 Days |

| Type | Jaw Type | Jaw Type | Bellows Type | Bellows Type | Jaw Type | Jaw Type |

| Allowable Misalignment | - | - | - | - | - | Angular Misalignment / Eccentricity / Axial Misalignment |

| Application | - | - | - | - | - | - |

| Allowable Torque Range(N•m) | 10.01 to 20.00 | 10.01 to 20.00 | 10.01 to 20.00 | 10.01 to 20.00 | 10.01 to 20.00 | 10.01 to 20.00 |

| Shaft Bore Dia. (machined) D1(mm) | 4 ~ 25 | 6 ~ 25 | 6 ~ 28 | 5 ~ 24 | 8 ~ 25 | - |

| Shaft Bore Dia. (machined) D2(mm) | 4 ~ 25 | 6 ~ 25 | 6 ~ 28 | 5 ~ 24 | 8 ~ 25 | - |

| Outer Dia. A(mm) | 32 ~ 42 | 32 ~ 42 | 40 | 40 | 42 | - |

| Overall Length W(mm) | 32 ~ 50 | 35 ~ 66 | 43 ~ 53 | 50 ~ 60 | 66 | - |

| Max. Rotational Speed Range(r/min) | - | - | - | - | - | 10,001 to 78,000 |

| Feature | - | - | - | - | - | Vibration Insulation |

| Body Material | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Resin |

| Category | - | - | - | - | - | - |

| Allowable Torque(Nm) | 4 ~ 8 | - | 4 | 4.5 | 34 | 12 |

| Max. Rotational Speed(r/min) | 12500 ~ 13000 | 12500 ~ 13000 | - | - | 12500 | 15000 ~ 40000 |

| Allowable Lateral Misalignment Range(mm) | - | - | - | - | - | 0.02 to 0.2 ~ 0.21 to 0.40 |

| Allowable Lateral Misalignment(mm) | - | - | 0.2 ~ 0.3 | 0.2 ~ 0.3 | - | 0.06 ~ 0.25 |

| Allowable Angular Misalignment(deg) | - | - | 1.5 ~ 2 | 1.5 ~ 2 | - | 0.8 ~ 1.2 |

| Buffer Part Material | Polyurethane | Polyurethane | - | - | Polyurethane | - |

| Disc Part Material | - | - | - | - | - | - |

| Bellows Part Material | - | - | Stainless Steel | Stainless Steel | - | - |

Loading...

Filter by:

Narrow search by specifying spec./dim.

-

Allowable Misalignment

-

Not Provided

Not Provided -

Angular Misalignment

Angular Misalignment -

Eccentricity

Eccentricity -

Axial Misalignment

Axial Misalignment

-

-

Application

- Standard

- Servo Motor

- Stepping Motor

- Encoder

-

Allowable Torque Range(N•m)

-

Shaft Bore Dia. (machined) D1(mm)

- 1

- 1.5

- 2

- 2.5

- 3

- 3.17

- 3.2

- 3.5

- 4

- 4.5

- 4.76

- 5

- 5.5

- 6

- 6.35

- 7

- 7.93

- 8

- 8.5

- 9

- 9.5

- 9.52

- 9.525

- 9.53

- 10

- 11

- 12

- 12.7

- 13

- 14

- 14.5

- 15

- 15.875

- 16

- 17

- 18

- 18.5

- 19

- 20

- 20.5

- 21

- 22

- 23

- 23.5

- 24

- 25

- 25.4

- 26

- 27

- 28

- 28.5

- 29

- 30

- 30.5

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 50

- 52

- 55

- 56

- 58

- 60

- 0635

- 09525

[4-28/1mm Unit(s)]

-

Shaft Bore Dia. (machined) D2(mm)

- 1

- 1.5

- 2

- 2.4

- 2.5

- 3

- 3.17

- 3.2

- 3.5

- 4

- 4.5

- 4.76

- 5

- 5.5

- 6

- 6.35

- 7

- 7.93

- 8

- 8.5

- 9

- 9.252

- 9.5

- 9.52

- 9.525

- 9.53

- 10

- 11

- 12

- K 12

- 12.7

- 13

- 14

- K 14

- 14.5

- 15

- 15.875

- 16

- K 16

- 17

- 18

- K 18

- 18.5

- 19

- 20

- K 20

- 21

- 22

- K 22

- 23

- 23.5

- 24

- 25

- 25.4

- 26

- 27

- 28

- 28.5

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 48

- 50

- 52

- 55

- 56

- 58

- 60

[4-28/1mm Unit(s)]

-

Outer Dia. A(mm)

- 6

- 6.4

- 6.5

- 8

- 9

- 9.5

- 10

- 12

- 12.7

- 13

- 13.5

- 14

- 14.5

- 15

- 15.5

- 15.9

- 16

- 16.1

- 16.5

- 16.6

- 16.8

- 17

- 17.5

- 18

- 19

- 19.1

- 19.5

- 20

- 21

- 22

- 22.2

- 24

- 24.5

- 25

- 25.4

- 25.5

- 26

- 26.2

- 26.5

- 26.6

- 27

- 27.3

- 28

- 29

- 30

- 31.7

- 31.8

- 32

- 32.5

- 33.3

- 34

- 34.4

- 35

- 36

- 38

- 39

- 39.5

- 40

- 40.5

- 41.0

- 41.3

- 42

- 42.5

- 43

- 44

- 44.5

- 45

- 46

- 47

- 48

- 49

- 50

- 53

- 53.6

- 54

- 54.5

- 55

- 56

- 57

- 58

- 60

- 62

- 63

- 64

- 64.5

- 65

- 66

- 66.5

- 67

- 68

- 69

- 69.9

- 70

- 73

- 74.5

- 75

- 77

- 79

- 79.5

- 80

- 81

- 82

- 83

- 85

- 87

- 88

- 90

- 93

- 94

- 94.5

- 95

- 99

- 100

- 102

- 104

- 104.5

- 105

- 109

- 110

- 112

- 115

- 117

- 118

- 119

- 120

- 122

- 125

- 126

- 129

- 135

- 136.5

- 138

- 140

- 143

- 144

- 150

- 152

- 155

- 157

- 160

- 161

- 168

- 169

- 170

- 175

- 178

- 185

- 190

- 194

- 200

- 208

- 210

- 214

- 215

- 225

- 246

- 255

- 260

- 262

- 276

- 285

- 290

- 308

- 320

- 346

- 370

- 420

-

Overall Length W(mm)

- 5.1

- 7.3

- 8.4

- 9

- 9.4

- 9.6

- 10

- 10.2

- 10.4

- 10.5

- 11.2

- 11.4

- 11.8

- 12

- 12.35

- 12.4

- 12.7

- 13

- 13.2

- 13.5

- 14

- 14.05

- 14.2

- 14.4

- 14.5

- 14.6

- 14.8

- 14.9

- 15

- 15.5

- 15.6

- 15.7

- 15.8

- 15.9

- 16

- 16.2

- 16.5

- 16.6

- 16.7

- 17

- 17.4

- 17.6

- 17.8

- 18

- 18.1

- 18.4

- 18.5

- 18.7

- 18.8

- 19

- 19.1

- 19.3

- 19.35

- 19.4

- 19.6

- 19.7

- 19.8

- 20

- 20.2

- 20.4

- 20.5

- 20.6

- 21

- 21.2

- 21.3

- 21.4

- 21.5

- 21.6

- 21.8

- 22

- 22.1

- 22.2

- 22.5

- 23

- 23.1

- 23.15

- 23.2

- 23.3

- 23.4

- 23.5

- 23.6

- 23.9

- 24

- 24.1

- 24.2

- 24.4

- 24.5

- 24.9

- 25

- 25.4

- 25.5

- 25.6

- 25.7

- 25.9

- 26

- 26.2

- 26.4

- 26.5

- 26.6

- 27

- 27.2

- 27.3

- 27.4

- 27.6

- 28

- 28.2

- 28.4

- 28.5

- 29

- 29.5

- 29.8

- 30

- 30.2

- 30.4

- 30.5

- 30.8

- 31

- 31.2

- 31.3

- 31.4

- 31.5

- 31.6

- 32

- 32.2

- 32.3

- 32.5

- 32.6

- 32.7

- 32.8

- 33

- 33.3

- 33.5

- 33.8

- 34

- 34.4

- 34.5

- 35

- 35.3

- 35.6

- 36

- 36.5

- 36.8

- 37

- 37.2

- 37.4

- 37.5

- 37.8

- 38

- 38.2

- 38.5

- 38.6

- 39

- 39.2

- 39.4

- 39.5

- 39.7

- 40

- 40.1

- 40.5

- 41

- 41.8

- 42

- 42.3

- 43

- 43.2

- 43.4

- 43.5

- 43.6

- 44

- 44.2

- 44.5

- 44.7

- 44.8

- 45

- 45.2

- 45.6

- 46

- 46.2

- 46.6

- 47

- 47.1

- 47.6

- 48

- 48.4

- 49

- 49.2

- 49.4

- 49.7

- 50

- 50.2

- 50.6

- 50.8

- 51

- 51.2

- 51.3

- 52

- 52.5

- 52.8

- 53

- 53.2

- 53.4

- 53.6

- 54

- 54.1

- 54.3

- 54.4

- 54.5

- 54.6

- 55

- 55.5

- 56

- 56.2

- 56.5

- 56.6

- 57

- 58

- 58.2

- 58.3

- 58.5

- 58.6

- 59.3

- 59.7

- 59.8

- 59.9

- 60

- 60.4

- 60.5

- 60.6

- 60.8

- 61

- 61.2

- 62

- 63

- 63.3

- 63.4

- 63.5

- 63.6

- 63.7

- 63.8

- 64

- 64.8

- 65

- 65.6

- 66

- 66.6

- 66.8

- 67

- 67.1

- 67.5

- 68

- 68.3

- 68.5

- 68.6

- 68.7

- 68.8

- 69

- 69.5

- 69.6

- 69.8

- 70

- 70.5

- 70.6

- 70.7

- 71

- 71.2

- 71.4

- 72

- 72.1

- 72.4

- 73

- 73.3

- 74

- 74.4

- 74.8

- 75

- 75.6

- 75.8

- 76

- 76.2

- 77

- 77.6

- 77.8

- 78

- 78.3

- 78.8

- 79

- 79.5

- 79.8

- 80

- 80.8

- 81

- 82

- 82.5

- 82.6

- 82.8

- 83

- 83.6

- 84

- 84.7

- 85

- 85.2

- 85.5

- 85.6

- 86

- 87.2

- 88

- 89

- 89.3

- 89.5

- 89.6

- 89.8

- 90

- 90.3

- 90.5

- 90.8

- 91

- 92

- 93

- 93.6

- 94

- 95

- 95.6

- 96

- 96.2

- 97

- 97.2

- 98

- 98.5

- 98.6

- 99

- 99.2

- 99.6

- 100

- 100.2

- 101

- 101.6

- 102

- 102.5

- 103

- 104

- 104.4

- 105

- 105.8

- 106

- 107

- 107.6

- 108

- 109

- 110

- 111

- 112

- 112.8

- 113

- 114

- 114.2

- 115

- 115.6

- 116

- 116.5

- 117

- 117.6

- 118

- 118.4

- 119.6

- 120

- 120.8

- 121

- 123

- 123.6

- 124

- 125

- 126

- 126.5

- 127

- 128

- 129

- 129.6

- 130

- 131

- 133

- 136

- 136.4

- 137.6

- 138

- 140

- 140.2

- 141

- 142

- 144

- 144.2

- 146

- 147

- 150

- 150.6

- 153.0

- 154

- 154.6

- 156.4

- 158

- 160

- 162

- 164

- 164.6

- 168

- 170

- 170.6

- 176

- 178.4

- 182.8

- 192.4

- 193

- 195

- 200

- 206

- 208.8

- 209.2

- 216

- 217

- 218

- 223

- 238

- 241.2

- 249.4

- 260

- 286.8

- 290

- 307

- 335

- 337.2

- 377

- 391

- 421

- 607

-

Max. Rotational Speed Range(r/min)

-

Feature

-

Body Material

-

Category

- Coupling Main Body

- Maintenance Components

-

Allowable Torque(Nm)

-

Max. Rotational Speed(r/min)

-

Allowable Lateral Misalignment Range(mm)

-

Allowable Lateral Misalignment(mm)

-

Allowable Angular Misalignment(deg)

-

Buffer Part Material

-

Disc Part Material

-

Bellows Part Material

Narrow search by specifying Brand

-

- MISUMI (10)

- NABEYA BI-TECH (17)

- MAEDLER (16)

- SUNGIL (10)

- MIKI PULLEY (7)

- R+W (6)

- ADVANCED (4)

- SAKAI MANUFACTURING (4)

- MIGHTY (3)

- KAYSEVEN (2)

- LINK (2)

- NIHON MINIATURE (2)

- ISEL (1)

- MITSUBOSHI BELTING (1)

- GANTER (0)

- KBK (0)

- SCH (0)

- KOYO ELECTRONICS INDUSTRIES (0)

- ORIENTAL MOTOR (0)

- KTR SYSTEMS (0)

- FESTO (0)

- IFM ELECTRONIC (0)

- NORELEM (0)

- KIPP (0)

- VMA (0)

- ABP ANTRIEBSTECHNIK (0)

Narrow search by specifying CAD data type

-

- 2D

- 3D

Narrow search by specifying lead time

-

- All

- Same day

- 3 Days or Less

- 4 Days or Less

- 5 Days or Less

- 6 Days or Less

- 7 Days or Less

- 8 Days or Less

- 9 Days or Less

- 10 Days or Less

- 11 Days or Less